- Geographic Information Systems (GIS)

- Geography is information about the earth's surface and the objects found on it, as well as a framework for organizing knowledge. GIS is a technology that manages, analyzes and disseminates geographic knowledge.

- Global Positioning Systems (GPS)

- A satellite navigation system used for precisely determining location and time anywhere on earth.

- International Standards Organization (ISO) 9000 and 14000 standards

- A system of verifiable standards for implementing total quality management in production processes. 9000 and 14000 both pertain to process; 9000 to production process and 14000 to environmental impact in manufacturing processes.

- Radio Frequency Identification Devices (RFID)

- Technologies that use radio waves to automatically identify people or objects.

- Total Quality Management (TQM)

- A customer- and quality-focused production management and service delivery system that relies on efficient and effective use of an entire organization.

- Voice-Over Internet Protocol (VOIP)

- Technology that allows for voice conversations to be carried over the Internet, generally lowering communication costs.

Glossary of Terms

Coffee entrepreneurs and roasting innovators who seek out and attempt to exploit new technologies, as well as those who crave the excitement of market-changing events, should find this "dawning of a new coffee age" tailor-made for them. For many roasters, however, the amount of information that is becoming available from those origins that are "coming on-line" will be simply overwhelming. In a market where coffee consumers have the same access to raw origin information as roasters, some roasters will prosper and some will perish. For the specialty coffee industry, as with many industries, it is indeed a brave new world, one built on an open exchange of verifiable information.

In the coffee industry, information technologies are taking hold globally, regionally and even at the farm level. The spread and exchange of information has brought many useful technologies to the coffee industry including radio frequency tracking (RFID), global positioning systems (GPS) and voice-over Internet protocol (VOIP). Additionally, the revolution in travel and communication technologies have helped spread the gospel of better management and production techniques to origin, such as total quality management (TQM) concepts and international standards organizations (ISO) procedures.

Growing Global

Perhaps the rising technologies that can most profoundly change the coffee market are geographic information systems technologies (GIST), the most popular of which are geographic information systems (GIS).GIS technology uses geography (information about the earth's surface and the objects found on it, as well as a framework for organizing knowledge) to manage, analyze and disseminate geographic knowledge.

In the coffee world, this means that GIS, coupled with more reliable and cheaper communications and the widespread availability of the Internet to producers, exporters, roasters and consumers alike, is creating a wealth of information about coffee and origin.

However, GIS is more than just a technology. It is an analytical methodology, sets of data, computer modeling, language and worldview all rolled into one. GIS relies on the revolution in communications that make it easier and cheaper to get reliable data from often far-flung and isolated geographic areas. Additionally, the increase in computing power has helped lay the groundwork for the coffee industry in its development of reliable GIS systems. This developing ability to pull divergent sets of information together makes data more accessible and presents it in an easy to understand and often visually stunning manner. This is quickly changing the way coffee market information is exchanged, and will most likely change the market itself.

GIS is a comprehensive way to collect, view and understand complex and interrelated datasets. GIS systems are developed to be inherently simple, open and user-friendly, often pulling together datasets from multiple sources. This multiple reporter/multiple user format allows for a more complete and comprehensive understanding of the physical world around us and our relationship to it. In the case of coffee, it is allowing us to better understand coffee's relationship to the environment and the people that depend on it for their livelihoods. It also allows for a high level of traceability and transparency at origin and eventually throughout the entire supply chain.

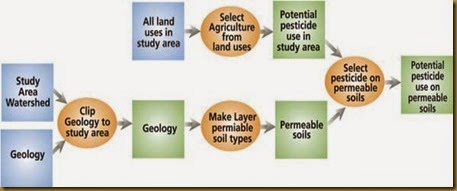

There are three ways that a comprehensive GIS system can be used to collate, explain and present data: a database view (geodatabase), map view (geovisualization) and model view (geoprocessing). Perhaps the easiest way to think about and understand GIS technology is just as data, map and process.

In the database view, data is collected and the dataset is collated, translated and stored in geographic terms. For example, a coffee grower gives relevant survey data to a collecting agency, including mailing address, number of residents, amount of land cultivated in coffee and amount of land cultivated in sustenance crops. The type and amount of data that can be expressed in this manner is nearly infinite. The data is processed and put into sets.

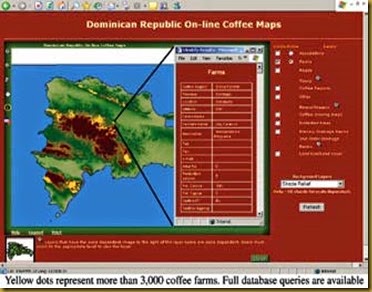

In the map view, the geographic datasets are formed into maps. A map is a set of intelligent maps representing the geographic data. These maps make it easier to visualize geographic datasets in multiple ways. In coffee, this is being used by international agencies, which take data sets from coffeegrowing regions and compile them onto high-resolution maps, helping to make the relevant coffee information, such as amount of area planted in coffee, visual.

The model view is a set of tools that allows new and different datasets to be built from current datasets and maps. This process is often used to display processes and effects of different variables upon a known system: modeling. Thirdparty certifying agencies can see the effect of one large coffee grower's use of pesticides on all downstream growers by utilizing existing datasets on watershed maps, geology, prevailing wind patterns, soil migration patterns and pesticides. The model can then be verified using traditional scientific testing and sampling techniques.

In short, it is through emerging GIS technology that growers, cooperatives, green brokers, specialty certifiers and shippers can give roasters the true transparency and traceability of specialty grade coffees that we have long requested. Additionally, this technology allows for the collection of reliable, concrete data to be used by governments, certifiers and international agencies in agricultural development and sustainability projects, allowing for better matching types of coffees and growing practices with the local environment.

Get Wired - Coffee-related GIS, GPS and interactive Internet sites

SCAA's producer GPS sitewww.scaa.org/whatis_producer_map.asp

SCAA's consumer GPS site

http://maps1.scaa.org/consumermap/viewer.htm

GeoCafe program site

http://edcintl.cr.usgs.gov/geocafe/

SITCA project

www.cafecentroamerica.com

GIS and allied technologies

www.gis.com

Pulling Back the Curtain As mentioned above, GIS is more than just a technology--it is a way of accessing, compiling and presenting data. The technology allows users to look at the same datasets in very different ways. It also allows users to shuffle different datasets into new information packets, expanding the end-users' ability to see connections not easily seen through traditional information analysis paradigms.

GIS can quickly and easily answer a variety of coffee-related questions, including:

- Where are certain coffees produced?

- How much coffee was produced in a region?

- What farms lie within an area?

- How much rainfall did an area receive?

- Type and amount of shade?

- Which farms belong to which co-ops?

- Per capita income within a region?

- What certifications are available within a region?

- Processing methods within a region?

- Watershed issues and flows within an area?

- Amount of coffee produced by certain farms?

- Type of processing used by a particular co-op or farm?

- How are individual coffees cupped?

- Who cupped and scored individual coffees?

- How long was the coffee in fermentation?

- How long was the cherry in transportation?

Putting GIS to Use

Currently, two projects that have been working to bring complementary GIS and information systems to the market are those run by GeoCafe and Sistema de Trazabiliadad de Cafe Caf de Alta Calidad (SITCA).

The Macro

The GeoCafe project is a partnership of the United States Geological Service's (USGS) National Center for Earth Resources (EROS), CATIE and ICAFE (Costa Rica), ANACAFE (Guatemala), and IDIAF and CODOCAFE (Dominican Republic). The project has been developed with funding from the USAID Quality Coffee Program.

The GeoCafe system is accessible through the Internet at http://edcintl.cr.usgs.gov/geocafe. From this portal, anyone can access the maps and information currently available from the participating associations and countries listed above. The GeoCafe system provides coffee information in two primary ways: through interactive maps (map/geovisualization) and as a query tool (process/ geoprocessing), thus allowing the different datasets to be accessed and compiled (data/geodatabase).

One only has to visit the GeoCafe website and read its objectives to truly glimpse the future of specialty green coffee. In addition to facilitating access to information over the Internet on the production, process and marketing of coffee, the project hopes to help growers establish direct contact with buyers, promote the mechanisms that would facilitate product monitoring and tracing, and assist in the creation of agricultural appellation systems.

Herein perhaps lie the beginnings of the solution for the cyclical coffee crisis: information (access and sharing), communication, appellation, market access and training made possible through technological innovation.

The Micro

SITCA is a software program and data collection system with a number of objectives. They include establishing a quality system composed of technical assistance, coffee training, infrastructure improvement, fund acquisition and long-term relationships between coffee growers, exporters and buyers. It is to be initially used as a quality control and processing tool for wet-mill managers, exporters, cooperative managers and certification personnel.The SITCA project is funded by Techno-Serve and the InterAmerican Development Bank's Central American Coffee Project (PCCA). Utilizing GIS principles, SITCA developer Rafeal Valdez created a system that he states, is "powerful, simple, and versatile" and designed to allow the user to monitor the "coffee chain from its harvest stage until its export."

Many of the partner country organizations--ANACAFE, Consejo Salvadoreno de Cafe Caf , Instituto Hondureno del Cafe Caf , Specialty Coffee Association of Nicaragua and ICAFE representing Guatemala, El Salvador, Honduras, Nicaragua and Costa Rica--have already held training classes to familiarize the users with the system.

The SITCA software is comprised of three components: coffee processing, wet mill infrastructure and machinery maintenance.

While the SITCA and GeoCafe projects have similar goals and can answer many of the same basic questions, they are, in fact, different projects and systems. SITCA lacks the sophisticated mapping sequences of GeoCafe. Additionally, SITCA is a bottom-up program focusing more exclusively on data collection and training of coffee producers and processors. GeoCafe, on the other hand, has more socioeconomic, geographic and climatic data. Although the two systems are different, they are complementary data-sharing systems. And through further utilization of GIS principles, each should strengthen the other as they both expand and continue to develop into new coffee-growing regions.

"Technology and information is important for development," says Maria Elena Krueger of Techno - Servo on the merits of SITCA technology. "Through this software, growers have access to and control of their own processes of coffee production in order to provide consistent quality coffee year after year."

The Pico

Both the SITCA and GeoCafe projects seek to improve quality and market access for coffee growers from many countries utilizing the latest in technologies or the benefits of falling prices on existing technologies. In the Cerrado of Minas Gerais in Brazil, however, many newer technologies are on display in one tightly run and quality-oriented organization: Daterra Farms.

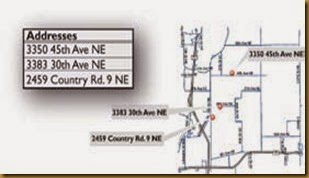

Daterra Farms is a 12,000-acre plantation owned by Luis Norberto Pascoal, businessman and author of the Aroma of Coffee: A Practical Guide for Coffee Lovers. Pascoal has a passion for espresso, quality and sustainability that is easily noticed when visiting the Daterra Farms. Daterra has subdivided its holdings into 88 mini-farms demarcated by coffee variety. The mini-farms are further divided into blocks, or quadras. This subdivision facilitates the accurate collection of data and lessens the effect of uncontrollable variables on the harvesting and processing of coffee.

With GPS and RFI tracking technologies, the division of the Daterra plantation allows staff to accurately track the coffee from the tree through the processing phase. By closely monitoring the blocks as the coffee develops, Daterra can harvest each section at its peak flavor. Morning strategy meetings are held every day during the harvest where the color-coded daily section map is the primary tool for directing the deployment of harvesting resources for the day.

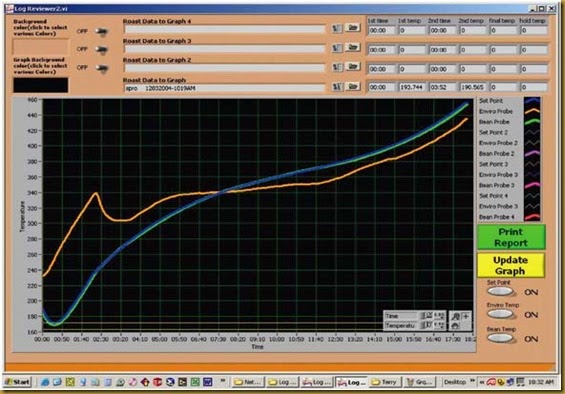

For Daterra, however, the use of technology to help track the bean on its path to quality does not end with the harvest, or even with the highly monitored milling and drying phases. Daterra has developed its own software and systems, the PENTA system, to ensure that the buyers and roasters who use their coffees get the exact flavor profiles they are looking for, every time. Daterra's cupping and blending systems, coupled with its state-of-the-art cupping labs and highly trained personnel seek to assist roasters in matching coffees to their roast and blending styles, while helping roasters match the coffees with consumer tastes.

Daterra's PENTA process system and ISO 14001 certification demonstrates its commitment to proper management and manufacturing procedures, and to lessen the environmental impact of coffee growing and processing. "The use of technology is fundamental to producing high-quality green beans consistently," Pascoal says. "Daterra is trying to become an example of what one coffee farm can do with technology and sustainability management."

Daterra, like the GeoCafe and SITCA projects, also relies heavily on partnerships to help further research into the heart of the bean. Daterra has research partnerships with the Minas Gerais state agricultural center, numerous Brazilian universities and, perhaps most impressively, an ongoing research relationship with IllyCafe. The Daterra commitment to sharing information and their use of geographic data aligns the company squarely with the GIS worldview.

Technology and the Internet have shrunk the world of the coffee roaster, while simultaneously expanding our ability to access information. Our mission as we continue to pursue the brass ring of quality is to stay current and open-minded. For so long, roasters have demanded traceability and transparency from our green brokers, coffee cooperatives, certifiers and even the growers. It is now our responsibility to learn to use the systems that have been developed at our urging. Through this process, we will reward those who wish to be our partners in consistently delivering quality to the specialty coffee consumer. And we are likely to find ourselves rewarded in the process as well.