Types of Probes

Nearly as many types of probes as there are letters in the alphabet have been manufactured. For the purposes of coffee roasters, we are only interested in two: thermocouples and RTDs. Thermocouples, by far the most widely used type of probe in coffee roasters, come in many types that roughly correspond to different temperature gradients and different media. Thermocouples measure temperature by using the known temperature gradients of dissimilar metals. This produces EMF (electromotive force) or voltage, which is then translated into a temperature and can be read by a repeater, controller or computer - thermocouples are non-linear. In coffee roasting equipment, J and K types are the most popular probes. Js can measure temperatures up to 1400°F while K types can measure up to 2300°F. J types are most often used in roasters and Ks are most often used to measure temperature in afterburners. Although Ks can be used in roasters the tighter range of Js make them more accurate at the temperatures associated with roasting coffee. RTDs (Resistance Temperature Device) measure temperature through temperature induced electrical resistance across the element. RTDs are linear, making them more accurate than thermocouples. RTDs have the added ability of being able to field calibrate errors out of systems. This calibration cannot be done with thermocouples. Although RTDs are more accurate than thermocouples, both are sufficiently accurate for use with coffee roasting equipment. Additionally, RTDs cost in the range of two to three times what a comparable thermocouple costs.

Uses of Probes in Coffee Roasting

Training and safety are closely linked in coffee roasting. Poorly trained personnel are themselves unsafe. Accurate and repeatable measurements make it easier and quicker to train beginning personnel and to provide on-going training and quality control assistance to experienced roasting personnel. Probes tied to controllers or high limit reset switches can virtually eliminate some types of roaster fires (drum fires) while lessening the impact of others (chaff and exhaust fires). Probe actuated alarms can make multi-tasking of roasting personnel easy and safe. Probes, controllers and alarms have helped reduce the stress of operating in a retail environment and have helped make it safe for retail roasters to talk on the phone again. Safety and training are strong reasons for adopting probes, but most roasters have adopted probes for more pragmatic reasons: accuracy and repeatability.

Roasters are constantly struggling with the two pillars of consistency: accuracy and repeatability. Without a level of accuracy there is no repeatability, without repeatability there is no consistency. Although accuracy and repeatability are connected, they are still two distinct and separate concepts. Generally accuracy is determined by equipment whereas repeatability has many factors affecting its performance. Of the two, repeatability is by far the most important and the hardest to attain. Accuracy depends on probe type and calibration of the system. Issues that affect accuracy are: type of sensor, calibration (Thermocouples have standard limits and special limits; while RTD’s have class A and class B element types), the ability to calibrate the system (probe and controller), size of the probe, placement, etc.- all of which have different tolerances. Additionally, because of the relatively low temperatures and slow temperature change throughout the roasting process, the accuracy required of a probe used in coffee roasting is easily achievable by most probe combinations. Once again accuracy has a definite affect on repeatability and the two are intimately intertwined: probe type, size and calibration all are elements of both. However, the single most important element of repeatability and hence consistency is the actual positioning of the probe.

Positioning of Probes for Accuracy & Repeatability

When we talk about repeatability, we are talking about the ability to measure the same temperature regardless of the size of the load being roasted. What we are most interested in when we roast different load sizes, is producing the same roast profile. We want our full loads to roast in the same amount of time and to the same temperature with the same degree of roast as our half loads. In order to obtain this we need to be measuring the same thing in both cases. We want to measure the beans regardless of the amount of coffee we have in the roaster.

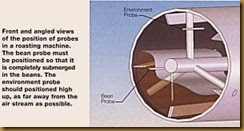

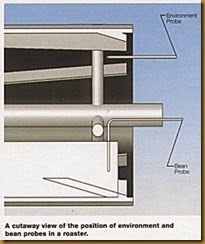

The only way to do this accurately is that the probe must measure the same thing in all cases - the media and the beans. Probes provide signals based on what they are measuring. Probes measure the area directly surrounding them, the air, the beans, and the drum. So if a probe is positioned so it is in the beans when running a full load, but above the mass of the beans when running a partial load, you’re not measuring the same thing, and you will not get the same results. The probe must be positioned so that it is completely submerged in the beans regardless of the amount of coffee in the drum.

Next, you want the probe located on the side of the drum that is rotating the beans in an upward direction. If the drum turns clockwise the probe should be on the left side of center when looking at the face plate. If the drum rotates counterclockwise, the probe should be located on the right side of center on the face plate. The probe should be positioned as low on the faceplate as possible, without interfering with anything. If the probe is still too high to be completely submerged in your smallest batch, then you will have a measure of inconsistency between batch sizes. Your smallest batch size will not be measured by the same standards as your fuller batches.

This leads to the question of how to get enough of the probe into the drum without contacting the agitators that help move the coffee in the drum, or the spokes that help support the weight of the drum on the shaft. These obstructions are often closer to the inside of the face plate than the minimum required immersion depth. This may lead to modification of the probe, this modification is fairly simple. Both thermocouples and RTDs have an outer metal sheath or tube that can be bent to allow enough of the probe to be inside the drum to get an accurate measurement. Bending the probe will also resolve the above issue of not being able to position the probe as low as you need to for your smaller batches. Probes can be bent around a mandrel (a pulley or rod will suffice) that is at least two times the diameter of the probe. Start the bend at least at the minimum immersion depth, to insure that you have the minimum in the drum, or at a point that will get the tip of the probe down to the desired position. Bend the probe 90 degrees, and then position the leg of the probe closer to the agitators than the face plate. Bending the probe can unfortunately, lead to another issue, the bent leg of the probe can act as a lever allowing the beans to push it out of position. This can cause the probe to make inaccurate or inconsistent readings, and can even lead to damage of the probe. Probe movement can be dealt with in two simple ways: 1) use of a compression fitting that will lock the probe in place, or 2) if there is enough of the probe protruding from the face plate, you could make a second bend outside the face plate allowing the sheath to rest against a fixed object or be clamped in place to prevent rotation.

By positioning the bean probe as described above, you will always be measuring the beans in the same manner, thus ensuring repeatability both between roasts and between batch sizes. With proper positioning even an inaccurate or un-calibrated probe can allow for consistency and repeatability.

But what about the positioning of an environment probe? All of the above information applies to the use of an environment probe as well as a bean probe. Immersion depth and media contact is just as important for environment probes as bean probes. The difference is that the media being measured is now the air (environment) in the roasting chamber. Since, when roasting, it is not possible to completely eliminate the influence of the coffee beans on the environment we must attempt to minimize it through correct positioning. When positioning the probe, keep it up as high as possible inside the drum, being careful to keep the probe as far out of the air stream as possible. If the environment probe is positioned in the air stream, the speed of the air across the probe will cause it to read higher than the actual temperature inside the drum. Additionally hot air rises inside the drum and is drawn to the front and out by the exhaust, leaving cooler air inside the drum. If the probe is located in this air stream, it will give you a false indication that you have adequately preheated the drum. Not preheating adequately can lead to extended roast times. This problem is often seen when using bean probes as the only indicator of preheat temperature, a task for the probe was not positioned for.

Safety, training, accuracy, repeatability and consistency- no other tool has provided so much for so little. The correct use of probes can be a valuable tool for any size roaster in any coffee operation. Temperature probes have helped to fuel the explosion of retail roasters and have spurred many a retail roaster to move into wholesaling. They have begun to change the language that roasters speak replacing common names (French, Full City, Italian etc…) with temperatures, times and curve profiles. Where once we might have said a dark French, we may now, more accurately, say a 141/2 minute roast to a drop temperature of 465 degrees F. For wholesale roasters the ability to accurately measure and record temperatures has made it easier to replace key roasting personnel without sacrificing either quality or efficiency. For consumers it has led to an increase of high-quality, consistently roasted coffees thereby expanding their choices and helping them to move away from lower grade commercially roasted coffees. But the greatest effect of all has been on the bean itself. Accurate and consistent temperature measurement has helped committed roasters to strive to develop the best roast profile for individual varietals, estates and crop years. And developing the bean is what roasting is really about.

Article initially published in Tea & Coffee - February/March, 2004

No comments:

Post a Comment