Tastes As Great As It Smells Coffee

(As reported in TechnoPack News)

In late 2006, a new coffee is coming to the coffee drinking consumer: Grand Bouquet Coffee. Grand Bouquet delivers the discerning coffee consumer a gourmet experience at a cut-rate price with coffee that "tastes as great as it smells!" According to Joe Raymond, marketing director of Great Scents Brands, Grand Bouquet Coffee "is putting a new spin on gourmet coffee through its unique coffee scented packaging." Mr. Raymond goes on to state that the packaging actually enhances and reinforces the pleasantness of the coffee by stimulating the olfactory receptors in the brain even while the great coffee smell of the package entices consumers to take a bag home. "This allows us to buy less expensive coffee and, through aromatic enhancement, turn it into gourmet grade coffee, truly magic," says Raymond. Selling at $4.99 for a 12-ounce bag, Grand Bouquet is priced well below other gourmet coffee brands currently offered in grocery stores.

THE PRECEDING PACKAGING PRODUCT is a bit of coffee science fiction. But, as with most sci-fi stories, the future that is portrayed is not far away. Computers that send messages, diagnose and heal illnesses, even think for themselves--these were all once only products of a sci-fi writer's imagination. The same is happening with coffee packaging: from packages that enhance the scent of coffee, heat themselves or keep tabs on their contents--if someone can think it up, then there is a good chance we'll see it on the shelves at some point in the future.

If, five or 10 years ago, you'd taken a poll of coffee industry professionals about the packaging progress they hoped and expected to see in the future, their list of priorities probably would have looked something like this: product quality and freshness, sustainable materials and better marketing options.

Today, the future of packaging is here, and it doesn't look at all like what we expected. While we sit around debating the freshness and environmental impacts of bags versus cans, the rest of the world has moved forward on the marketing front. Just in the last few years, marketing products like inexpensive professional quality label printers and new packaging finishes have made their way into the industry. And, now, a new future of packaging has arrived: Smart Packaging. This movement, for coffee and other industries, is here to stay. And it's large--it has trade magazines (The Smart Packaging Journal); white papers, and conferences (Intelligent & Smart Packaging USA).

While the terms smart and intelligent packaging might conjure up images of gee-whiz packages that freeze, open, cook themselves or even whisper to you from the shelf, it is really much less exciting than that. Smart packaging is very simply a package designed to do more than to convey or hold a product. To quote Packaging Materials & Technologies, a leading consultancy for the packaging industry, "Forget about all those numerous definitions-- active, diagnostic, intelligent, smart, functional, enhancement--to describe smart packaging. Just stick to "smart" and figure it's all one big continuum of functionality. In fact, think of smart as meaning clever, neat or "wow" and you'll get the picture."

Today, many specialty coffee roasters subscribe to the theory and some of the concepts behind smart packaging, many without even knowing it. Unusual or stunning graphics, packages in custom shapes and sizes, and even freshness valves, can all easily fall under the rubric of smart packaging. But, what of the truly gee-whiz, geeky or techno stuff in packaging today? We are now entering a period where packaging is increasingly used to monitor freshness, track distribution, heat and cool products and even communicate with the consumer. In other words, packaging and packaging materials are becoming more communicative, interactive and functional. In many cases the packaging material is being developed and manufactured to do jobs that are currently done by hand, or left undone.

As markets become increasingly global, the packaging industry is quickly responding to the challenges of long-term storage, long-distance shipping and cross cultural differences. Currently food and beverage packaging makes up the lion's share of the industry; nearly 60 percent of the packaging industry is for food and beverage, including coffee. According to NanoMarkets, a technology research firm, smart packaging for food and beverage will increase from the current $4.4 billion to $14.1 billion by the year 2013. Smart packaging includes such technologies as radio frequency identification (RFID), olfaction packaging, self-adjusting freshness indicators and self-heating packaging that may all have some level of relevancy for the coffee industry.

The second category is defined as packages made smart through engineering of the packaging whether by mechanical, chemical, electronic or electrical means and active interaction of the product and the package itself. That is, the package must have some desired effect on the product or the product must have some desired effect on the package. For the specialty coffee industry three types of these technologies--olfactory packaging, interactive freshness indicators and self-heating packaging--are already being used, with the potential for many more on the way.

That barrier has now been crossed. A company called ScentSational Technologies creates coffee-scented packaging by introducing FDA-approved food-grade flavors and fragrances directly into the manufacture of the packaging materials; these are the same flavors and fragrances that are currently used in flavored coffee. The scent is embedded into the material during manufacture, thus a bag manufactured for coffee would smell like coffee before it was ever near a bean.

The implications of this are huge, of course. Theoretically the process could be very discriminating, choosing only those coffee flavors associated with freshness and even those indicative of certain origins. Maintaining and enhancing say the blueberry in a Harrar, or the lemon of a great Yirgacheffe or any other distinct aromatic profile desired, including fresh ground coffee. Or a coffee may smell as fresh as when it was first bagged as the packaging transfers the fresh coffee smell to the coffee itself. This type of technology would have no bearing on products pulled for spoilage or safety reasons, but could increase the shelf life of products such as coffee, which is pulled off shelves for scent and flavor degradation. Olfaction packaging also may have applications in the flavored coffee market, flavoring the coffee through the bag instead of flavoring the bean directly.

In addition, this technology is currently being used for beverage packaging--the aroma of fresh coffee is built into coffee lids used for carryout, as well as potentially into the ready-to-drink cold drinks. Envision drinking a cup of crappy convenience store coffee that smells so fresh you can taste the quality, and you get the idea.

According to Steven Landau, chief technology officer for ScentSational Technologies, this type of packaging will grow. "Based on consumer research and shelf-life testing, olfaction packaging will have widespread appeal and long-lasting applications for food packaging," he says. "It makes products last longer and gives consumers the sensibility of freshness."

Olfaction packaging technology, not unlike organic acid manipulation (Wired For Roast, Roast magazine, March/April 2006), may have very serious long term implications for the specialty coffee industry, and especially for roasters and growers. Although no doubt there are good uses that can come from this technology, if not managed well, this technology could be used to hide old, faded coffees, add elements to coffee that were not present in the first place, and in general to deceive consumers as to the freshness, aroma or origins of the coffees they are purchasing and drinking.

This active smart packaging uses existing technology to sense the fall or rise of single or multiple chemical indicators to estimate when a coffee should be consumed by to ensure a pre-determined level of freshness; if there is a change in the rate of product degradation, the use-by date physically changes to reflect the new reality, guaranteeing that the consumer has an accurate date to make a determination of freshness based on their own coffee consumption patterns.

This technology is already being used to sense the ripeness of packaged pears through the sensing of the level of aroma. This smart package, called RipeSense, changes the sensor on the face of the packaging to indicate the true level of ripeness. A related technology is being used in consumer dairy packaging to prove freshness and reduce unnecessary waste in plastic milk cartons.

To sum, it could soon be possible to have an accurate useby / freshness date based on the science of measurable chemical parameters; a date that consumers can easily read and understand and that is accurate. The measuring instrument will be embedded in the packaging material during the manufacturing process. Thus, the package itself becomes a more accurate sensor of freshness than any measure or scheme currently in use. This type of technology for coffee has a strong potential market on the specialty side, as it is specialty roasters who have the most to gain through better and more accurate freshness monitoring.

As great as more accurate freshness parameters for coffee would be, it is unlikely that the specialty coffee industry as a whole will adopt these technologies and conceive the measures that would lead to widespread adoption. Perhaps a few intrepid specialty roasters that are truly interested in freshness will utilize this new technology and move forward alone. These companies could hopefully gain an edge in the market while proving to the consumer that freshness is a serious issue for great tasting coffee. Better freshness regimes can also help farmers, as old coffee is pulled from shelves and fresher coffee is offered in its place. The day specialty coffee is truly treated as a perishable agricultural product will be a great one indeed for growers, roasters and consumers alike. Perhaps Interactive Freshness Indicators can help bring the specialty coffee industry to this new dawning.

So, how does it work? The self-heating can utilizes a chemical reaction of calcium oxide CaO (quicklime) and water to heat the product. The CaO H2O mixture is isolated from the coffee by an inner liner, and the insulated outer can keeps the already liquefied product warm without burning the drinker. All consumers need to do is turn the can upside down, pop the bottom and watch the little indicator button to know when it's hot enough to drink. Clever indeed, but like a teleportation project gone terribly wrong, sometimes things don't go as planned.

In the spring of 2006, a short year after coming to market, reports began to surface of the lattes getting too hot, leaking chemicals into the coffee, and even exploding. In April of 2006, the product was pulled from store shelves. Currently the FDA is looking into the complaints and all involved parties are no doubt busy preparing for court (if not over consumer actions, then certainly against one another).

The lesson here is that not all emerging technologies are ready for market, and in some cases, perhaps never should have come to market at all. At any rate, be sure that the American coffee consumer has not seen the last of self-heating smart packages.

Currently, RTLS are matchbox-sized tags with small batteries that can be easily attached to any container. These devices send a signal that is picked up by a network which records and logs the time and location. Such a system could be used in the specialty coffee industry to track an estate green from source through a broker to a roaster then onto a store shelf. It could also very easily be utilized as part of a product verification regime, such as those being sought for organics, or to ensure the receipt of current crop coffees. Additionally with a little imagination these types of systems could also have value to interested consumers. One thing is for sure: RTLS should have a place in the specialty coffee industry as growers, brokers and roasters seek out more and better market differentiation through verification.

SALs are the next generation of RFIDs and an improvement over the older RTLS. SAL systems are thin labels that contain an integrated circuit and a power source. The system must also have a receiver (often handheld) to read the data and some sort of a data collection and retaining system (generally a PC- or Internet based program) to enable an interested party to accumulate, track and process the data. The flexibility offered in SAL systems is much greater than that currently offered in RTLS-based tracking and traceability programs.

Active RFIDs including both RTLS and SAL signals can currently be read by a wide, and ever more widening, group of receivers. Among the products able to be used as RFID receivers and/or relays are: WiFi, Bluetooth, GPS, Cell Phone, Infrared, GSM, GPRS and Passive RFID. This ever-increasing circle of available and, in many cases inexpensive, receiving devices make these emerging packaging technologies perfect for reporting, tracking and verification programs.

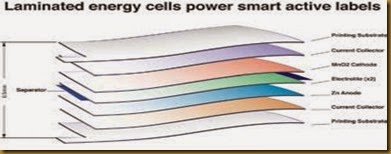

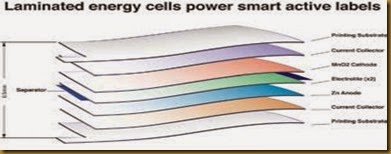

Although these systems are already in use in the market, they are currently somewhat cost-prohibitive. According to Baruch Levanon, chairman of the Smart Active Labels Consortium (SAL-C), a non-profit trade oriented interest group, "the goal is an item-level disposable tag that can be tailored not only for function but for size and space requirements ensuring low-cost, real-time data." Currently SALs cost a few dollars per unit. However, Levanon says, "When in the future, we should get to a fully-printed label, the cost will drop to a few cents." Utilizing energy cells made from inks, some SAL labels can be laminated not unlike conventional labels. With printed batteries, microelectronic circuitry and printed antennas these labels can be less than 1mm thick and should be able to be produced by traditional printing practices, making the technology cheaper and helping to lead to more widespread use of such devices.

So how do, or can, RFID packaging technologies affect the specialty coffee industry? Currently some RFID tracking is being done at origin, and no doubt this practice will become more common as traceability becomes an ever larger issue for the industry. There is simply no conceivable reason why this technology, as costs drop, should not also eventually be adopted by specialty brokers and roasters for verification of origin, organic transparency, handling and the time tracking of shipments. Furthermore RFID technology coupled with PC and/or Internet based roast data-logging systems could conceivably reduce the administrative costs of handling organic, fair-trade and other certified coffees for growers, brokers and roasters alike. A system such as the Organic Process Evaluation Network (OPEN) system outlined in the OPEN graphic (page 69) would add a new level of integrity. Such a system would be more secure; reducing the chance of any company or individual gaming the certification system. By reducing the likelihood of consumer fraud while allowing the consumer to access the verification process the specialty coffee industry would be taking a giant proactive leap forward.

Through the use of existing, albeit new, systems and devices such as SALs, RTLS, active RFID capable devices, PC-based control systems and the Internet, roasters could turn a production-oriented system into a marketing tool and hopefully expand the market for specialty coffee through the trust engendered by a fool-proof system that allows verification at the consumer level. With smart packaging, the package becomes the source of conveyance, marketing and active verification of certified products direct to the consumer.

Perhaps it will not be long before we see a press release like this:

The Global Specialty Coffee Association announces its new Guaranteed Freshness program for consumer packaging. The program will ensure the freshness of pre-packaged whole-bean coffee through a sophisticated chemical-sensing unit manufactured into the packaging material. Interested coffee companies need only buy the packaging material, pre-formed or roll stock, to participate. This is a licensed technology and is the result of years of collaboration between the packaging industry, food scientists specializing in the chemical make-up of coffee, and other interested coffee professionals working through the GSA. Licensing fees will be used by the association to fund further coffee-oriented research and for marketing the Guaranteed Freshness program.

We can only look into the future, and hope.

www.packagingdigest.com

Smart Active Labels Consortium SAL-C

www.sal-c.org

IDTechEx, packaging research and analysis

www.idtechex.com

Discovery Channel Ripesense report

www.exn.ca/dailyplanet/view

PackWire, news on packaging technologies

www.PackWire.com

School of Packaging at Michigan State University

packaging.msu.edu

Self-heating container video

www.ontech.com/video

(As reported in TechnoPack News)

In late 2006, a new coffee is coming to the coffee drinking consumer: Grand Bouquet Coffee. Grand Bouquet delivers the discerning coffee consumer a gourmet experience at a cut-rate price with coffee that "tastes as great as it smells!" According to Joe Raymond, marketing director of Great Scents Brands, Grand Bouquet Coffee "is putting a new spin on gourmet coffee through its unique coffee scented packaging." Mr. Raymond goes on to state that the packaging actually enhances and reinforces the pleasantness of the coffee by stimulating the olfactory receptors in the brain even while the great coffee smell of the package entices consumers to take a bag home. "This allows us to buy less expensive coffee and, through aromatic enhancement, turn it into gourmet grade coffee, truly magic," says Raymond. Selling at $4.99 for a 12-ounce bag, Grand Bouquet is priced well below other gourmet coffee brands currently offered in grocery stores.

THE PRECEDING PACKAGING PRODUCT is a bit of coffee science fiction. But, as with most sci-fi stories, the future that is portrayed is not far away. Computers that send messages, diagnose and heal illnesses, even think for themselves--these were all once only products of a sci-fi writer's imagination. The same is happening with coffee packaging: from packages that enhance the scent of coffee, heat themselves or keep tabs on their contents--if someone can think it up, then there is a good chance we'll see it on the shelves at some point in the future.

If, five or 10 years ago, you'd taken a poll of coffee industry professionals about the packaging progress they hoped and expected to see in the future, their list of priorities probably would have looked something like this: product quality and freshness, sustainable materials and better marketing options.

Today, the future of packaging is here, and it doesn't look at all like what we expected. While we sit around debating the freshness and environmental impacts of bags versus cans, the rest of the world has moved forward on the marketing front. Just in the last few years, marketing products like inexpensive professional quality label printers and new packaging finishes have made their way into the industry. And, now, a new future of packaging has arrived: Smart Packaging. This movement, for coffee and other industries, is here to stay. And it's large--it has trade magazines (The Smart Packaging Journal); white papers, and conferences (Intelligent & Smart Packaging USA).

While the terms smart and intelligent packaging might conjure up images of gee-whiz packages that freeze, open, cook themselves or even whisper to you from the shelf, it is really much less exciting than that. Smart packaging is very simply a package designed to do more than to convey or hold a product. To quote Packaging Materials & Technologies, a leading consultancy for the packaging industry, "Forget about all those numerous definitions-- active, diagnostic, intelligent, smart, functional, enhancement--to describe smart packaging. Just stick to "smart" and figure it's all one big continuum of functionality. In fact, think of smart as meaning clever, neat or "wow" and you'll get the picture."

Today, many specialty coffee roasters subscribe to the theory and some of the concepts behind smart packaging, many without even knowing it. Unusual or stunning graphics, packages in custom shapes and sizes, and even freshness valves, can all easily fall under the rubric of smart packaging. But, what of the truly gee-whiz, geeky or techno stuff in packaging today? We are now entering a period where packaging is increasingly used to monitor freshness, track distribution, heat and cool products and even communicate with the consumer. In other words, packaging and packaging materials are becoming more communicative, interactive and functional. In many cases the packaging material is being developed and manufactured to do jobs that are currently done by hand, or left undone.

As markets become increasingly global, the packaging industry is quickly responding to the challenges of long-term storage, long-distance shipping and cross cultural differences. Currently food and beverage packaging makes up the lion's share of the industry; nearly 60 percent of the packaging industry is for food and beverage, including coffee. According to NanoMarkets, a technology research firm, smart packaging for food and beverage will increase from the current $4.4 billion to $14.1 billion by the year 2013. Smart packaging includes such technologies as radio frequency identification (RFID), olfaction packaging, self-adjusting freshness indicators and self-heating packaging that may all have some level of relevancy for the coffee industry.

Smart and Intelligent

Smart and intelligent packaging falls into two distinct categories. The first is those packages that are made intelligent through the attachment of sensors or RFID devices to an existing package, such as those used in traceability.The second category is defined as packages made smart through engineering of the packaging whether by mechanical, chemical, electronic or electrical means and active interaction of the product and the package itself. That is, the package must have some desired effect on the product or the product must have some desired effect on the package. For the specialty coffee industry three types of these technologies--olfactory packaging, interactive freshness indicators and self-heating packaging--are already being used, with the potential for many more on the way.

Smells Good, Tastes Great?

Scientists have long known of the positive psychological effects of pleasing scents to the moods of humans. And probably marketing people have been trying to manipulate them for just as long. The sense of smell is the only sense that is processed directly in the limbic lobe, the emotional center, of the brain, making it perhaps the most valuable sense to marketers as it bypasses the logical portion of the brain. We are all familiar with the perfume pages in fashion magazines, scratch and sniff scents and other such marketing material, but how about the smell of fresh-roasted/ground coffee emanating from barrier packaging on the store shelves?That barrier has now been crossed. A company called ScentSational Technologies creates coffee-scented packaging by introducing FDA-approved food-grade flavors and fragrances directly into the manufacture of the packaging materials; these are the same flavors and fragrances that are currently used in flavored coffee. The scent is embedded into the material during manufacture, thus a bag manufactured for coffee would smell like coffee before it was ever near a bean.

The implications of this are huge, of course. Theoretically the process could be very discriminating, choosing only those coffee flavors associated with freshness and even those indicative of certain origins. Maintaining and enhancing say the blueberry in a Harrar, or the lemon of a great Yirgacheffe or any other distinct aromatic profile desired, including fresh ground coffee. Or a coffee may smell as fresh as when it was first bagged as the packaging transfers the fresh coffee smell to the coffee itself. This type of technology would have no bearing on products pulled for spoilage or safety reasons, but could increase the shelf life of products such as coffee, which is pulled off shelves for scent and flavor degradation. Olfaction packaging also may have applications in the flavored coffee market, flavoring the coffee through the bag instead of flavoring the bean directly.

In addition, this technology is currently being used for beverage packaging--the aroma of fresh coffee is built into coffee lids used for carryout, as well as potentially into the ready-to-drink cold drinks. Envision drinking a cup of crappy convenience store coffee that smells so fresh you can taste the quality, and you get the idea.

According to Steven Landau, chief technology officer for ScentSational Technologies, this type of packaging will grow. "Based on consumer research and shelf-life testing, olfaction packaging will have widespread appeal and long-lasting applications for food packaging," he says. "It makes products last longer and gives consumers the sensibility of freshness."

Olfaction packaging technology, not unlike organic acid manipulation (Wired For Roast, Roast magazine, March/April 2006), may have very serious long term implications for the specialty coffee industry, and especially for roasters and growers. Although no doubt there are good uses that can come from this technology, if not managed well, this technology could be used to hide old, faded coffees, add elements to coffee that were not present in the first place, and in general to deceive consumers as to the freshness, aroma or origins of the coffees they are purchasing and drinking.

Freshness Counts

Another area of interest for coffee roasters is the possibility of more accurate freshness indicators for specialty coffee. Currently, it is nearly impossible for a consumer to know whether a coffee is beyond its freshness threshold unless they buy it directly out of the cooling bin of the local roaster. Even if the industry had an agreed-upon program (we don't) for date stamping and/or a use by freshness threshold, it would hardly be accurate due to the vast variances in the way roasters currently package coffee. With whole-bean coffee packaging alone the packaging permutations are nearly incalculable; some roasters de-gas, some don't; some valve pack, some don't; some vacuum pack, some don't; some nitrogen flush, some don't; some do all the above and some do none and on and on it goes. So, even if the industry could agree on a standard, it would hardly be an accurate measure of coffee that was beyond a selling point for consumers. Enter Self- Adjusting Use By/Sell By Dates.This active smart packaging uses existing technology to sense the fall or rise of single or multiple chemical indicators to estimate when a coffee should be consumed by to ensure a pre-determined level of freshness; if there is a change in the rate of product degradation, the use-by date physically changes to reflect the new reality, guaranteeing that the consumer has an accurate date to make a determination of freshness based on their own coffee consumption patterns.

This technology is already being used to sense the ripeness of packaged pears through the sensing of the level of aroma. This smart package, called RipeSense, changes the sensor on the face of the packaging to indicate the true level of ripeness. A related technology is being used in consumer dairy packaging to prove freshness and reduce unnecessary waste in plastic milk cartons.

To sum, it could soon be possible to have an accurate useby / freshness date based on the science of measurable chemical parameters; a date that consumers can easily read and understand and that is accurate. The measuring instrument will be embedded in the packaging material during the manufacturing process. Thus, the package itself becomes a more accurate sensor of freshness than any measure or scheme currently in use. This type of technology for coffee has a strong potential market on the specialty side, as it is specialty roasters who have the most to gain through better and more accurate freshness monitoring.

As great as more accurate freshness parameters for coffee would be, it is unlikely that the specialty coffee industry as a whole will adopt these technologies and conceive the measures that would lead to widespread adoption. Perhaps a few intrepid specialty roasters that are truly interested in freshness will utilize this new technology and move forward alone. These companies could hopefully gain an edge in the market while proving to the consumer that freshness is a serious issue for great tasting coffee. Better freshness regimes can also help farmers, as old coffee is pulled from shelves and fresher coffee is offered in its place. The day specialty coffee is truly treated as a perishable agricultural product will be a great one indeed for growers, roasters and consumers alike. Perhaps Interactive Freshness Indicators can help bring the specialty coffee industry to this new dawning.

Too Hot to Handle?

And now we come to the final, and perhaps the most unexpected packaging development: self-heating packaging. On November 7, 2004, at the Pack Expo trade show in Chicago, Ill., a little known company, OnTech Delaware, debuted the first North American developed and manufactured self-heating container. The container was designed and marketed with the ready-to-drink tea, cocoa, soups and coffee markets in mind. The product soon attracted the attention of Beverage Partners LLC, a company working with the famous chef and restaurateur, Wolfgang Puck. By January 2005, Wolfgang Puck's lattes were headed to American store shelves to battle with other more traditional forms of lattes.So, how does it work? The self-heating can utilizes a chemical reaction of calcium oxide CaO (quicklime) and water to heat the product. The CaO H2O mixture is isolated from the coffee by an inner liner, and the insulated outer can keeps the already liquefied product warm without burning the drinker. All consumers need to do is turn the can upside down, pop the bottom and watch the little indicator button to know when it's hot enough to drink. Clever indeed, but like a teleportation project gone terribly wrong, sometimes things don't go as planned.

In the spring of 2006, a short year after coming to market, reports began to surface of the lattes getting too hot, leaking chemicals into the coffee, and even exploding. In April of 2006, the product was pulled from store shelves. Currently the FDA is looking into the complaints and all involved parties are no doubt busy preparing for court (if not over consumer actions, then certainly against one another).

The lesson here is that not all emerging technologies are ready for market, and in some cases, perhaps never should have come to market at all. At any rate, be sure that the American coffee consumer has not seen the last of self-heating smart packages.

Tracing Paper

Radio frequency identifying devices (RFID), which allow the identification of a product through radio frequencies, come in various forms, including: smart seals, key fobs, and condition monitoring tags, in-transition condition monitors and time and temperature indicators. Some RFIDs are active, automatically relaying information such as a change in condition, or an out of limits situation to a central monitoring system. Others are passive and draw their energy as they pass under or through a system such as a hand-held reader or conveyor mounted apparatus. Although many types of RFID hold relevancy for the specialty coffee industry, perhaps the two with the most potential for coffee roasters are real time locator systems (RTLS) and smart active labels (SALs).

Currently, RTLS are matchbox-sized tags with small batteries that can be easily attached to any container. These devices send a signal that is picked up by a network which records and logs the time and location. Such a system could be used in the specialty coffee industry to track an estate green from source through a broker to a roaster then onto a store shelf. It could also very easily be utilized as part of a product verification regime, such as those being sought for organics, or to ensure the receipt of current crop coffees. Additionally with a little imagination these types of systems could also have value to interested consumers. One thing is for sure: RTLS should have a place in the specialty coffee industry as growers, brokers and roasters seek out more and better market differentiation through verification.

SALs are the next generation of RFIDs and an improvement over the older RTLS. SAL systems are thin labels that contain an integrated circuit and a power source. The system must also have a receiver (often handheld) to read the data and some sort of a data collection and retaining system (generally a PC- or Internet based program) to enable an interested party to accumulate, track and process the data. The flexibility offered in SAL systems is much greater than that currently offered in RTLS-based tracking and traceability programs.

Active RFIDs including both RTLS and SAL signals can currently be read by a wide, and ever more widening, group of receivers. Among the products able to be used as RFID receivers and/or relays are: WiFi, Bluetooth, GPS, Cell Phone, Infrared, GSM, GPRS and Passive RFID. This ever-increasing circle of available and, in many cases inexpensive, receiving devices make these emerging packaging technologies perfect for reporting, tracking and verification programs.

Although these systems are already in use in the market, they are currently somewhat cost-prohibitive. According to Baruch Levanon, chairman of the Smart Active Labels Consortium (SAL-C), a non-profit trade oriented interest group, "the goal is an item-level disposable tag that can be tailored not only for function but for size and space requirements ensuring low-cost, real-time data." Currently SALs cost a few dollars per unit. However, Levanon says, "When in the future, we should get to a fully-printed label, the cost will drop to a few cents." Utilizing energy cells made from inks, some SAL labels can be laminated not unlike conventional labels. With printed batteries, microelectronic circuitry and printed antennas these labels can be less than 1mm thick and should be able to be produced by traditional printing practices, making the technology cheaper and helping to lead to more widespread use of such devices.

So how do, or can, RFID packaging technologies affect the specialty coffee industry? Currently some RFID tracking is being done at origin, and no doubt this practice will become more common as traceability becomes an ever larger issue for the industry. There is simply no conceivable reason why this technology, as costs drop, should not also eventually be adopted by specialty brokers and roasters for verification of origin, organic transparency, handling and the time tracking of shipments. Furthermore RFID technology coupled with PC and/or Internet based roast data-logging systems could conceivably reduce the administrative costs of handling organic, fair-trade and other certified coffees for growers, brokers and roasters alike. A system such as the Organic Process Evaluation Network (OPEN) system outlined in the OPEN graphic (page 69) would add a new level of integrity. Such a system would be more secure; reducing the chance of any company or individual gaming the certification system. By reducing the likelihood of consumer fraud while allowing the consumer to access the verification process the specialty coffee industry would be taking a giant proactive leap forward.

Through the use of existing, albeit new, systems and devices such as SALs, RTLS, active RFID capable devices, PC-based control systems and the Internet, roasters could turn a production-oriented system into a marketing tool and hopefully expand the market for specialty coffee through the trust engendered by a fool-proof system that allows verification at the consumer level. With smart packaging, the package becomes the source of conveyance, marketing and active verification of certified products direct to the consumer.

The Future Is Now

RFID, SAL, olfaction packaging, interactive indicators: all of these smart technologies seem to be a long way from where most specialty coffee roasters are today. And yet it was not so long ago that roasters were debating the very efficacy of bean probes and digital controllers. And for the world of the working roaster, some of these technologies hold promise (self-adjusting use/by freshness indicators, RFID), while others may offer grave threat (olfaction packaging). Some may help us connect more directly with consumers and expand our businesses and our industry, while some may threaten the very foundation of our operational paradigms, our businesses and perhaps our industry itself. Whatever develops from these technologies, it is vitally important that those roasters in the specialty end of the industry pay very close attention to the developments occurring in the packaging industry.Perhaps it will not be long before we see a press release like this:

The Global Specialty Coffee Association announces its new Guaranteed Freshness program for consumer packaging. The program will ensure the freshness of pre-packaged whole-bean coffee through a sophisticated chemical-sensing unit manufactured into the packaging material. Interested coffee companies need only buy the packaging material, pre-formed or roll stock, to participate. This is a licensed technology and is the result of years of collaboration between the packaging industry, food scientists specializing in the chemical make-up of coffee, and other interested coffee professionals working through the GSA. Licensing fees will be used by the association to fund further coffee-oriented research and for marketing the Guaranteed Freshness program.

We can only look into the future, and hope.

Further Reading on Smart Packaging Technologies

Packaging Digestwww.packagingdigest.com

Smart Active Labels Consortium SAL-C

www.sal-c.org

IDTechEx, packaging research and analysis

www.idtechex.com

Discovery Channel Ripesense report

www.exn.ca/dailyplanet/view

PackWire, news on packaging technologies

www.PackWire.com

School of Packaging at Michigan State University

packaging.msu.edu

Self-heating container video

www.ontech.com/video

Great information you've posted! I think finding out lots of online coffee information is so helpful for roasting the beans and learning nice techniques.

ReplyDeleteFinding high quality coffee beans online can be just as difficult as finding them in person. So many times you can't taste ahead of time and I'm at a loss for figuring out how to choose which bean is right for me. If anyone knows how to find the best place to buy coffee online, please let me know!

I read your blog frequently and I just thought I’d say keep up the amazing work! Medium roast coffee

ReplyDelete