PERHAPS NO COFFEE SCENARIO is more unnerving to a professional specialty coffee roaster than visiting an account only to be served a truly horrible cup of coffee. As roasters, we can put all our energies into crafting a truly great coffee only to have the whole endeavor go to hell at the end of the supply chain.

As disastrous as that scenario may be, however, a far greater fear is this: that large commercial roasters will figure out how to close the taste gap between specialty coffees and commercial coffees. As coffee consumers' tastes change for the better and specialty roasters continue to erode the market share of the bigger commercial players, these large companies will continue to bring their great resources to bear on the taste deficiencies currently found in their cups.

This article will touch on technologies that have repercussions on both of the above scenarios. On one hand, technology has advanced to allow roasters more and better control over the brewing process, even when it occurs off-site. On the other, technologies are beginning to emerge that allow commercial roasters to try and breach the taste/quality ramparts specialty roasters have so arduously defended through specialty price differentials.

It has only been a few years since coffee roasters began to use temperature probes and PID controllers to help control the roast process. The widespread adoption of this technology allowed the roasting community to have more substantive exchanges of information and sparked experimentation and innovation in profile roasting that continue to this day. The PID movement within the espresso community is following much the same path. PID controls are beginning to be seen in new espresso machine designs and are an easy and relatively inexpensive upgrade to existing machines.

For most baristi and retailers, the goal is temperature stabilization for a consistent product, but for an intrepid group of coffee professionals and espresso aficionados alike, the accurate and real-time nature of PID controllers is allowing for more and repeatable experimentation of the effects of different extraction temperatures, times and pressures on different origins and blends. More importantly however, may be the development of a common language for the innovators to exchange and verify each other's work.

The second tool is a device that accurately measures water temperature at the brew head. This piece of equipment is named the Espresso Machine Thermofilter Temperature Device, but is commonly called the Scace Device after its creator, Greg Scace.

The Scace Device is a portable troubleshooting tool that marries with existing temperature measuring technology to measure espresso extraction temperatures at an individual group head. The device is deceptively simple and easy to use: one only need purchase the correct size Scace Device for their espresso machine and plug into any number of easily purchased handheld temperature readers, such as a Fluke. Although simple, the development of a puck to mimic the flow rate of a properly tamped and loaded portafilter is truly an ingenious advance in accurate extraction temperature measurement. More importantly for professional roasters, or their representatives, it provides a way to troubleshoot customer's extraction problems, and tweak their machines for maximum flavor extraction with a minimum of labor. Additionally, it can be a valuable tool for experimenting with different espressos in the roasting lab; helping roasters gain a better understanding of the role of extraction temperature upon individual coffees and in extending the specialty roaster's control over the cup produced through their roasting efforts. This tool has the added benefit of being relatively inexpensive as well.

The idea that different brewing cycles affect the perceived organic acids in brewed coffee (phosphoric, malic, lactic, acetic, citric, quinic, cholorgenic) is not new to roasters. Organic acids, being partially heat-determined, are affected similarly in the brewing cycle and the roasting process. Thus, in both roasting and brewing, time and temperature are the key variables that can be manipulated to produce different profiles. The key words for both processes are control, consistency and repeatability.

This new generation of drip brewers is full of smart elements that help ensure the brewing of better-tasting and more consistent cups of coffee. The most widely adopted innovations include pre-infusion functions, temperature and water regulation, and multi-profile brew settings (brew recipes). Brewer manufacturers currently appear to be in a technology race, each attempting to incorporate and then leapfrog their competitors' latest innovations.

Of all the recent brewer advancements, one of the most interesting is a new system that allows various machines to "talk" to each other. For example, Bunn's new generation BrewWise grinders can write the brewing profile of a specific coffee onto a chip encased in the brew basket. This chip technology then allows the grinder to "talk" to the compatible brewer, telling the brewer what coffee is in the basket and thereby setting the brewing profile for that specific coffee. Additionally, utilizing a PC and a recipewriting program, knowledgeable roasters can gain brew control over all accounts using the same system by simply downloading the recipes onto the brewers and grinders.

And therein lies a serious advancement in the evolution of brewers--the interface of existing PC technologies with the function and form of coffee brewing and grinding. The use of PCs in the process begins to open the door for better communication and data sharing not only between the wholesale roaster and their account, but also eventually between the roasting equipment and brewer itself.

Next up in the gee-whiz brewing category are systems such as the Clover 1, which are designed to bridge the gap between espresso and drip at the retail level. This adjustable brewer is defining a new class of brewer for the retail environment: single-serve. Utilizing a unique press/vacuum brewing method and PID loops, these brewers give the operator direct control over not just brew amounts, but brew times and temperatures, and even allowing for adjustability of water dosage to account for the absorption rates of different coffees and or different roasts. Programmable defaults allow for the "locking in" of preferred brew profiles where time or training prevents operator determined custom cups. In other words, this is a brewer that can brew a custom cup of coffee nearly every time, or create a consistent cup regardless of amount brewed.

The basic concepts involved in profile brewing are fairly simple: time, temperature, fl ow rates, grind size (surface area) and their combined affects on the taste of the coffee in the cup. However, applying the concepts in the everyday world of the professional coffee roaster is still an evolving thing. Determining and "locking in" the correct profiles, as well as the ability to consistently repeat, is where the brewing manufacturers are working now.

Programmable "smart brewers" that can profile brew for different origins and blends are nearly upon us. Time will only tell when and if these technologies come to fruition, and if they gain widespread acceptance in the real world. But one thing is certain--these technologies have the ability to radically change the working environment of the professional roaster. With repeatable, programmable brewers, roasters would have the ability to control the bean from the roaster through to the consumer of the brewed beverage. Matching the inherent taste characteristics of a raw coffee to its optimum roast profile and then on through to the corresponding optimum brew profile is a level of process control that would have seemed fantasy a mere decade ago.

In order to take full advantage of the possibilities that profile brewing presents, more definitive and verifiable taste work needs to be done. Additionally, roasters will need to interface more with brewer manufacturers as well as their own commercial customers, especially specialty retailers. Properly programming brew profiles will require a level of understanding of the brewing process and its effect on taste that few roasters currently possess.

Even as many roasters are still struggling to learn the intricacies of profile roasting, they may find themselves overwhelmed if the promise of profile brewing develops too fast. But, one thing is certain, the science of roasting and the science of brewing are quickly moving toward one another. As roasters, we need to be able to understand the developments in both to help further our comprehensive knowledge of the science of coffee.

As early as April 1997, an internal working paper passed between the Specialty Coffee Institute (forerunner of the Coffee Quality Institute) and the Kenya Coffee Research Foundation, comparing levels of phosphoric acids between Kenya's SL28 and other East African cultivars. The intent was to isolate why certain Kenyan coffees had such high relative levels of phosphoric acids, thereby creating a pleasantly sweet cup, and to help farmers eventually reproduce this effect through good agricultural practices. Much good information about organic acids and their role in producing a better cup was obtained through these research efforts. But, one of the more interesting experiments occurred when researchers manipulated the coffees by adding phosphoric acid to a Colombian in amounts that approached those of the vaulted Kenyans.

"Experiments in which phosphoric acid was added to other coffee origin brews significantly altered acid profiles to levels almost identical to Kenyan coffees," says Joseph Rivera, director of science and technology for the SCAA.

In other words, the Specialty Coffee Institute was able to "spike" other origins with enough phosphoric acid to mimic a true Kenyan, even though this was not the original stated intent of their study. Which begs the question: is it possible to buy one coffee and use it as a base to create another more desirable or valuable coffee? Utilizing the correct technology, it appears the answer is yes.

However, creating a coffee in the lab just to see if it can be done, and trying to create coffees economically, are two completely different undertakings. Laboratory-created coffees are not subject to the same market forces that coffees for consumption have to contend with. In order to create a coffee in an economically efficient manner, it would appear to require certain existing technologies: a High Performance Liquid Chromatography (HPLC) system to map the organic acids in brewed coffee and some sort of intelligent or smart brewer that could measure and add these organic acids into the brewing process, perhaps utilizing existing brewer bypass technology. It would also require a mass marketer of brewed coffee to achieve the economies of scale necessary to make such a scenario economically feasible.

Two of the three requirements already exist--HPLC and large sellers of brewed coffee--and the third is probably being developed as you read this. The implications of this type of flavor manipulation to the professional coffee roaster could be profound. For growers of certain origins that command premiums for uniqueness, such a development could be disastrous.

However, developments like these are not necessarily nightmare scenarios. A lot depends on who utilizes the technology and for what market(s). If, for instance, a large C-store chain invested in such technology and used it to upgrade the taste of its existing coffee line, the negative affects on the existing specialty market might be negligible, and could possibly have a positive effect by introducing more American consumers to better-tasting coffee, even if that coffee was "created" in the brewer. If a consumer "tasting" a Kenyan created in such a way wished to brew it at home, they would, with existing technology, need to go to the source and buy a true Kenyan in order to come close to the same taste they had been introduced to at the C-store. C-store coffee customers are currently considered to be coffee drinkers that are beyond the reach of the American specialty coffee industry.

There's another possible twist to this futuristic scenario: the development of these technologies for home brewers. It is not beyond the realm of possibility that someday coffee consumers will be able to input the coffee they wished to drink that morning and, regardless of what coffee went into the brewer, out would pop the taste of 2005's Brazil Cup of Excellence winner.

However this scenario plays out, or if it develops at all, it is vitally important that professional coffee roasters be involved in the discussion that is sure to surround it. As much as the use of smart brewers and organic acid mapping to "create" coffees seems beyond the reach of existing technologies, it is not beyond the realm of possibilities. It was not so long ago that genetically modified foods and irradiation of foods for human consumption seemed as far-fetched as creating brewed coffee origins through organic acid manipulation. For many of us this type of technological innovation may have moral and humanitarian implications as well as business and professional ones. It is therefore imperative that roasters of all stripes pay close attention to newly developing technologies if they wish to have a say in the direction that these and other technologies push our industry.

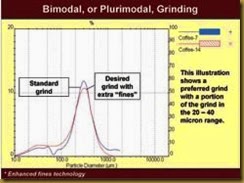

So what is bimodal grinding? According to Scott Will, of Modern Processing Equipment, bimodal grinding creates a "grinding methodology, provides a grind, or particle size distribution, that allows users to control not only the average grind size, but also to introduce a percentage of smaller particles, or "fines," into the grinding process to improve coffee extraction characteristics." In roaster terms it is a method for "profile grinding" to obtain a desired extraction result and to ensure repeatability and consistency.

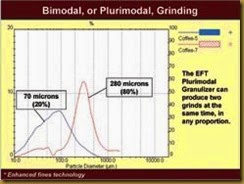

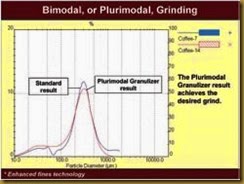

Bimodal grinding allows an operator to select two grind particle sizes in desired mix percentages and combines the grinds for a consistent final product. This allows finer particles to be used to expand the surface area for extraction (chemical need/taste) while using the larger particles to allow for proper water flow (physical need/time) during the extraction process. Once the correct percentages and sizes are known, it is simply a matter of entering the parameters into the programmable logic controller (PLC) automation of the grinder. These new functions allow for the measuring of particle and density size as the ground coffee exits the grinder. Not unlike newer roasting control systems, which seek to use real time measurements to make profile adjustments, this is doing the same, only with grinding instead of roasting. As in roasting, the watchwords in grinding have become control and consistency.

To most specialty roasters, this type of equipment is well beyond where many of them will go, or even want to go for that matter. It was developed primarily for the espresso pod industry and has applications in the capsule and cartridge coffee delivery systems areas as well. What it does demonstrate however is how serious other segments of our industry are about closing the quality/taste gap as it relates to consumers. It is also worth noting that technology has a tendency to trickle down -- finding more and more applications as the price of components fall and the initial research and development investments are recovered eventually allowing for more companies to utilize the technology in new and exciting ways.

Are we as roasters to fear a future where coffee is created by computer chips embedded in inexpensive home brewers? Or will the future bring an unprecedented amount of control to roasters from plant to cup? Will we as roasters be able to harness and direct the promise of the emerging technologies to move ever closer to the ideal of the "perfect cup"? Or will we be victims of innovations for which we fail to grasp the market implications? The choice, at least in part, will be ours to make.

www.coffeed.com

www.coffeegeek.com

www.baristaguildofamerica.org

As disastrous as that scenario may be, however, a far greater fear is this: that large commercial roasters will figure out how to close the taste gap between specialty coffees and commercial coffees. As coffee consumers' tastes change for the better and specialty roasters continue to erode the market share of the bigger commercial players, these large companies will continue to bring their great resources to bear on the taste deficiencies currently found in their cups.

This article will touch on technologies that have repercussions on both of the above scenarios. On one hand, technology has advanced to allow roasters more and better control over the brewing process, even when it occurs off-site. On the other, technologies are beginning to emerge that allow commercial roasters to try and breach the taste/quality ramparts specialty roasters have so arduously defended through specialty price differentials.

The Espresso Discussion

No other group of coffee people utilizes the Internet to more positive effect than those involved in the evolving discussion over espresso. Through websites, blogs and posting boards, they discuss everything from espresso equipment to single origins, proper espresso roast profiles to specific taste profiles. It is not unusual to find aficionados, baristi, equipment manufacturers, retailers and roasters all lending their opinions, backgrounds and experiences to the developing espresso discussions. These Internet discussions have begun to lead to the use and understanding of at least two tools that attempt to unlock the secret of a great espresso and perhaps more importantly, to reproduce it consistently. These tools, one old and one new, are proportional integral derivative (PID) controllers and espresso machine thermofilter temperature devices, also known as Scace devices.It has only been a few years since coffee roasters began to use temperature probes and PID controllers to help control the roast process. The widespread adoption of this technology allowed the roasting community to have more substantive exchanges of information and sparked experimentation and innovation in profile roasting that continue to this day. The PID movement within the espresso community is following much the same path. PID controls are beginning to be seen in new espresso machine designs and are an easy and relatively inexpensive upgrade to existing machines.

For most baristi and retailers, the goal is temperature stabilization for a consistent product, but for an intrepid group of coffee professionals and espresso aficionados alike, the accurate and real-time nature of PID controllers is allowing for more and repeatable experimentation of the effects of different extraction temperatures, times and pressures on different origins and blends. More importantly however, may be the development of a common language for the innovators to exchange and verify each other's work.

The second tool is a device that accurately measures water temperature at the brew head. This piece of equipment is named the Espresso Machine Thermofilter Temperature Device, but is commonly called the Scace Device after its creator, Greg Scace.

The Scace Device is a portable troubleshooting tool that marries with existing temperature measuring technology to measure espresso extraction temperatures at an individual group head. The device is deceptively simple and easy to use: one only need purchase the correct size Scace Device for their espresso machine and plug into any number of easily purchased handheld temperature readers, such as a Fluke. Although simple, the development of a puck to mimic the flow rate of a properly tamped and loaded portafilter is truly an ingenious advance in accurate extraction temperature measurement. More importantly for professional roasters, or their representatives, it provides a way to troubleshoot customer's extraction problems, and tweak their machines for maximum flavor extraction with a minimum of labor. Additionally, it can be a valuable tool for experimenting with different espressos in the roasting lab; helping roasters gain a better understanding of the role of extraction temperature upon individual coffees and in extending the specialty roaster's control over the cup produced through their roasting efforts. This tool has the added benefit of being relatively inexpensive as well.

Profile Brewing for Drip Coffee

The technological advances that are occurring on the espresso side are mirrored on the drip brewing side--only in this case, it is profile brewing that is coming to the forefront. "Profile brewing involves manipulating the way water is applied to the grounds producing alternate flavor profiles," says Randy Pope, the head of Bunn's Coffee Lab. For example, applying water at a given rate in the brewing process as opposed to having the water delivered at intervals throughout the cycle (pulse brewing). The differences in the two brewing cycles can significantly affect the taste profile of the individual coffees, resulting in sometimes radically different coffees in the cup.The idea that different brewing cycles affect the perceived organic acids in brewed coffee (phosphoric, malic, lactic, acetic, citric, quinic, cholorgenic) is not new to roasters. Organic acids, being partially heat-determined, are affected similarly in the brewing cycle and the roasting process. Thus, in both roasting and brewing, time and temperature are the key variables that can be manipulated to produce different profiles. The key words for both processes are control, consistency and repeatability.

This new generation of drip brewers is full of smart elements that help ensure the brewing of better-tasting and more consistent cups of coffee. The most widely adopted innovations include pre-infusion functions, temperature and water regulation, and multi-profile brew settings (brew recipes). Brewer manufacturers currently appear to be in a technology race, each attempting to incorporate and then leapfrog their competitors' latest innovations.

Of all the recent brewer advancements, one of the most interesting is a new system that allows various machines to "talk" to each other. For example, Bunn's new generation BrewWise grinders can write the brewing profile of a specific coffee onto a chip encased in the brew basket. This chip technology then allows the grinder to "talk" to the compatible brewer, telling the brewer what coffee is in the basket and thereby setting the brewing profile for that specific coffee. Additionally, utilizing a PC and a recipewriting program, knowledgeable roasters can gain brew control over all accounts using the same system by simply downloading the recipes onto the brewers and grinders.

And therein lies a serious advancement in the evolution of brewers--the interface of existing PC technologies with the function and form of coffee brewing and grinding. The use of PCs in the process begins to open the door for better communication and data sharing not only between the wholesale roaster and their account, but also eventually between the roasting equipment and brewer itself.

Next up in the gee-whiz brewing category are systems such as the Clover 1, which are designed to bridge the gap between espresso and drip at the retail level. This adjustable brewer is defining a new class of brewer for the retail environment: single-serve. Utilizing a unique press/vacuum brewing method and PID loops, these brewers give the operator direct control over not just brew amounts, but brew times and temperatures, and even allowing for adjustability of water dosage to account for the absorption rates of different coffees and or different roasts. Programmable defaults allow for the "locking in" of preferred brew profiles where time or training prevents operator determined custom cups. In other words, this is a brewer that can brew a custom cup of coffee nearly every time, or create a consistent cup regardless of amount brewed.

The basic concepts involved in profile brewing are fairly simple: time, temperature, fl ow rates, grind size (surface area) and their combined affects on the taste of the coffee in the cup. However, applying the concepts in the everyday world of the professional coffee roaster is still an evolving thing. Determining and "locking in" the correct profiles, as well as the ability to consistently repeat, is where the brewing manufacturers are working now.

Programmable "smart brewers" that can profile brew for different origins and blends are nearly upon us. Time will only tell when and if these technologies come to fruition, and if they gain widespread acceptance in the real world. But one thing is certain--these technologies have the ability to radically change the working environment of the professional roaster. With repeatable, programmable brewers, roasters would have the ability to control the bean from the roaster through to the consumer of the brewed beverage. Matching the inherent taste characteristics of a raw coffee to its optimum roast profile and then on through to the corresponding optimum brew profile is a level of process control that would have seemed fantasy a mere decade ago.

In order to take full advantage of the possibilities that profile brewing presents, more definitive and verifiable taste work needs to be done. Additionally, roasters will need to interface more with brewer manufacturers as well as their own commercial customers, especially specialty retailers. Properly programming brew profiles will require a level of understanding of the brewing process and its effect on taste that few roasters currently possess.

Even as many roasters are still struggling to learn the intricacies of profile roasting, they may find themselves overwhelmed if the promise of profile brewing develops too fast. But, one thing is certain, the science of roasting and the science of brewing are quickly moving toward one another. As roasters, we need to be able to understand the developments in both to help further our comprehensive knowledge of the science of coffee.

Organic Acid Manipulation (The Frankenstein Scenario)

As the development of smart brewers becomes a reality and as roasters and other coffee entrepreneurs learn more about the make-up of the taste of coffee, we have to be cognizant of the possibility of the manipulation of these technologies to "create" coffees.As early as April 1997, an internal working paper passed between the Specialty Coffee Institute (forerunner of the Coffee Quality Institute) and the Kenya Coffee Research Foundation, comparing levels of phosphoric acids between Kenya's SL28 and other East African cultivars. The intent was to isolate why certain Kenyan coffees had such high relative levels of phosphoric acids, thereby creating a pleasantly sweet cup, and to help farmers eventually reproduce this effect through good agricultural practices. Much good information about organic acids and their role in producing a better cup was obtained through these research efforts. But, one of the more interesting experiments occurred when researchers manipulated the coffees by adding phosphoric acid to a Colombian in amounts that approached those of the vaulted Kenyans.

"Experiments in which phosphoric acid was added to other coffee origin brews significantly altered acid profiles to levels almost identical to Kenyan coffees," says Joseph Rivera, director of science and technology for the SCAA.

In other words, the Specialty Coffee Institute was able to "spike" other origins with enough phosphoric acid to mimic a true Kenyan, even though this was not the original stated intent of their study. Which begs the question: is it possible to buy one coffee and use it as a base to create another more desirable or valuable coffee? Utilizing the correct technology, it appears the answer is yes.

However, creating a coffee in the lab just to see if it can be done, and trying to create coffees economically, are two completely different undertakings. Laboratory-created coffees are not subject to the same market forces that coffees for consumption have to contend with. In order to create a coffee in an economically efficient manner, it would appear to require certain existing technologies: a High Performance Liquid Chromatography (HPLC) system to map the organic acids in brewed coffee and some sort of intelligent or smart brewer that could measure and add these organic acids into the brewing process, perhaps utilizing existing brewer bypass technology. It would also require a mass marketer of brewed coffee to achieve the economies of scale necessary to make such a scenario economically feasible.

Glossary of Terms

- High Pressure Liquid Chromatography (HPLC)

- A form of liquid chromatography used to separate compounds that are dissolved in a solution. HPLCs are Ideal for separating organic acids within liquid coffee.

- Proportional Integral Derivative (PID)

- Controller A type of controller utilizing a feedback loop. The output of the controller (CV) is calculated taking into account the error (e) from a user-defined setpoint (SP) and the measured process variable (PV). The PID functions allow for the user to determine the amount of error and to adjust it out, allowing for a high level of stability within a control system.

- Programmable Logic Controllers (PLCs)

- Small computers programmed to automate specific processes.

- Bimodal/Plurimodal Grinding

- Allows operators to reintroduce fines into the grind at a desired percentage while still controlling average grind particle size to increase flavor extracted from the coffee. Also called profile grinding.

However, developments like these are not necessarily nightmare scenarios. A lot depends on who utilizes the technology and for what market(s). If, for instance, a large C-store chain invested in such technology and used it to upgrade the taste of its existing coffee line, the negative affects on the existing specialty market might be negligible, and could possibly have a positive effect by introducing more American consumers to better-tasting coffee, even if that coffee was "created" in the brewer. If a consumer "tasting" a Kenyan created in such a way wished to brew it at home, they would, with existing technology, need to go to the source and buy a true Kenyan in order to come close to the same taste they had been introduced to at the C-store. C-store coffee customers are currently considered to be coffee drinkers that are beyond the reach of the American specialty coffee industry.

There's another possible twist to this futuristic scenario: the development of these technologies for home brewers. It is not beyond the realm of possibility that someday coffee consumers will be able to input the coffee they wished to drink that morning and, regardless of what coffee went into the brewer, out would pop the taste of 2005's Brazil Cup of Excellence winner.

However this scenario plays out, or if it develops at all, it is vitally important that professional coffee roasters be involved in the discussion that is sure to surround it. As much as the use of smart brewers and organic acid mapping to "create" coffees seems beyond the reach of existing technologies, it is not beyond the realm of possibilities. It was not so long ago that genetically modified foods and irradiation of foods for human consumption seemed as far-fetched as creating brewed coffee origins through organic acid manipulation. For many of us this type of technological innovation may have moral and humanitarian implications as well as business and professional ones. It is therefore imperative that roasters of all stripes pay close attention to newly developing technologies if they wish to have a say in the direction that these and other technologies push our industry.

Bimodal Grinding

Often, one technological innovation begets another. Such is the case with bimodal grinding, also often called plurimodal. This advancement in grinding was created as a direct result of the development of commercial espresso pods and the new single-serve capsules. It is an attempt to help get a better and more consistent-tasting product from these newer extraction methods.So what is bimodal grinding? According to Scott Will, of Modern Processing Equipment, bimodal grinding creates a "grinding methodology, provides a grind, or particle size distribution, that allows users to control not only the average grind size, but also to introduce a percentage of smaller particles, or "fines," into the grinding process to improve coffee extraction characteristics." In roaster terms it is a method for "profile grinding" to obtain a desired extraction result and to ensure repeatability and consistency.

Bimodal grinding allows an operator to select two grind particle sizes in desired mix percentages and combines the grinds for a consistent final product. This allows finer particles to be used to expand the surface area for extraction (chemical need/taste) while using the larger particles to allow for proper water flow (physical need/time) during the extraction process. Once the correct percentages and sizes are known, it is simply a matter of entering the parameters into the programmable logic controller (PLC) automation of the grinder. These new functions allow for the measuring of particle and density size as the ground coffee exits the grinder. Not unlike newer roasting control systems, which seek to use real time measurements to make profile adjustments, this is doing the same, only with grinding instead of roasting. As in roasting, the watchwords in grinding have become control and consistency.

FIGURE1

Standard grind distribution for a well-maintained roller grinder.

FIGURE 2

A more desirable particle distribution for an espresso pod application.

FIGURE 3

Results of the bimodal process in action, producing both the "fines" and the primary grinds simultaneously.

FIGURE 4

The final distribution of the grinds measured after blending.

Are we as roasters to fear a future where coffee is created by computer chips embedded in inexpensive home brewers? Or will the future bring an unprecedented amount of control to roasters from plant to cup? Will we as roasters be able to harness and direct the promise of the emerging technologies to move ever closer to the ideal of the "perfect cup"? Or will we be victims of innovations for which we fail to grasp the market implications? The choice, at least in part, will be ours to make.

Espresso Discussion Bulletin Boards

www.roastersguild.orgwww.coffeed.com

www.coffeegeek.com

www.baristaguildofamerica.org

Extended Readings

- Alchemy in the Roasting Lab: The discovery of organic acids, part 1 and 2

- Roast magazine, March/April & May/June 2005

- Taking Control: PID settings and roasting controls

- Roast magazine, March/April 2005

- Temperature Control

- The Watlow Educational Series Book Five, Watlow Controls, Inc.

- Coffee's Acid Test

- Coffee & Cocoa International, November/ December 1998

The idea that spiking Colombian coffee with phosphoric acid may make it similar to a Kenyan SL28 seem to be contradicted by the research paper http://www.coffeeresearch.org/research/phosphate1.pdf, in which Joseph Rivera assisted. Could you please cite the paper conducted by the Kenya Coffee Research Foundation in 1997?

ReplyDelete