Profile management is a key component of our daily routine at the Cinnamon Bay Coffee roastery. We use roast profiles for new product development, quality control and as our mainstay in consistency for our production roasts. Keeping the roast profiles between the navigational beacons is our requirement for each and every roast we complete. That's not to say that we don't color outside the lines on occasion. But when we do, we record every step of the process just in case the result is astounding in the cup. We then have the data required to roast the same profile next time and repeat the experience.

A profile is simply a set of data, often in graphic form, that portrays the significant features of something--in this case, from roasting a batch of coffee. A profile can be portrayed as an outline, summary, report, run down, synopsis or sketch. The form it takes is up to the roaster collecting the data. Keeping it consistent so that the information is easy to understand and recall is a good start to building a profile system.

1. Identify profile.

Identifying a profile is the first step in profile management. This is easily accomplished by collecting data on each roast and creating a sketch of the results. Data collection can be simple or complex; a yellow notepad and a stopwatch are a great place to start. It's easier to follow the profile if there is a clear map of the data to follow through the next roast. To simplify the process, create a roast log with all the vital information and start recording.

2. Design roast log.

There are dozens of options for designing a roast log and creating roast profiles. Batch number, type of coffee and lot number are all good considerations that will make inventory, tracking and reporting easier. This is especially true in roasting facilities that operate under the guidelines of specific certification programs. A complete roast log also can make a product recall plan easier to implement. Day, date and start time of each roast are important, too. The start time shows efficiencies in time management. Roasters in extreme environments also might want to create a space to note weather conditions that might affect the outcome of the roast. Examples could range from extreme cold conditions to sudden thunderstorms. At Cinnamon Bay, we also incorporate an entry to log maintenance performed on the roaster that day.

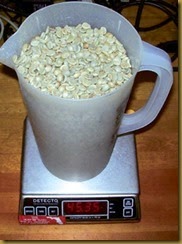

3. Weigh and record.

4. Set pre-heat.

Next, determine and note the correct "pre-heat temperature" for the various batch sizes. It takes some practice, but it's a manageable variable that gets easier with time. Pre-heat temperature is based on the capacity of your roaster, the weight of green to be roasted and the desired point of equilibrium. The pre-heat temperature will be considerably higher for a full batch than for a partial batch. Because the energy requirements are greater for a full batch, we can use maximum energy output from the burners, but that amount of energy is too much to control in a partial batch. A good starting point would be 100 percent gas output to pre-heat for a full batch and 50 percent gas for a half-batch, keeping in mind that the half-batch pre-heat temperature will be lower. Remember that a smaller batch doesn't require the same amount of energy as a full load, and too much energy makes it nearly impossible to manage a profile. It's hard to slow down a roast once it starts running because of the amount of heat being generated. Green weight and pre-heat temperature will determine the point of equilibrium (often called the "turning point").

5. Point of equilibrium.

"Point of equilibrium" is when the temperature of the green coffee is equal to that of the roasting environment. This should occur about one minute after the green coffee is dropped in. The pre-heat temperature of the roast environment reading will decrease when the cooler green coffee is introduced. The temperature will fall rapidly as the green coffee absorbs energy. Once the point of equilibrium is established, the green coffee starts absorbing energy, and the temperature reading will begin to climb. Profile management demands that the point of equilibrium is the same for each roast of a specific coffee regardless of batch size. A full batch or a half batch will be assured a more consistent roast result if the same point of equilibrium is used. Point of equilibrium gives the roaster a starting line to begin the actual profile process. The desired point of equilibrium will be determined by the specific roast profile set by the cup demands of each coffee. Point of equilibrium is managed by adjustments made to the pre-heat temperature.

6. Frequency of log.

Decide the frequency of temperature reading necessary to collect enough data to complete the profile. Time and temperature are an important combination to monitor as the roast moves forward. This is where the stopwatch comes in; record the bean temperature at regular intervals. From the point of equilibrium, we begin the climb to first crack. This "rate of rise" is determined by the profile points and the applied energy to reach the points. The rate of rise can be illustrated as the temperature increases over time. It's important to manage the forward momentum to achieve the desired roast profile and the "curve" we are looking for. Adjusting energy output will keep the rate of rise on track.

7. Set hold temperature.

8. Watch and adjust.

Now that the path to "first crack" has been determined, it's important to stay on track to reach first crack at the target time. We've already set the path for the rate of rise with the help of a hold temperature. Watch time and temperature to assure that first crack occurs both when and where it should based on the profile set for the specific coffee. Most coffees will crack near 385 degrees Fahrenheit. That's simply the science of the roast. There's not a lot of variable to control with that parameter. However, the time at which the first crack occurs and the path the coffee takes to get there will play a huge part in overall cup quality.

9. Final temperature.

The path from first crack to final temperature is determined by the amount of time desired to reach the final point. Roasters have varying opinions on the correct time element, and of course it will be partly a result of the final temperature. Some roasters like to back off the heat and coast through the final phase of the roast. Regardless of the technique, the process still can be managed by plotting the time and temperature grid, resulting in a profile with enough information that the entire process can be repeated.

10. Stop, drop and cool.

No comments:

Post a Comment